41 welding shop safety worksheet

PDF Safety and Health guide | Welding Health and Safety Welding Health and Safety SS-832 | March 2015 Page | 5 Carbon arc cutting "arc gouging" is an arc cutting process in which metals to be cut are melted by the heat of a carbon arc. The molten metal is removed by a blast of air. This is a method for cutting or removing metal by melting it with an electric arc and then blowing ... Welding Shop Safety Worksheets - Learny Kids Displaying top 8 worksheets found for - Welding Shop Safety. Some of the worksheets for this concept are Shop safety, Arc welding safety guide, Safety health of welders, Basic shop safety t u d e t h a d o u t, Degrees that welding fabrication, Degrees that welding fabrication, Lesson plans for module 29101 15 w safety, Arc welder.

Welding Safety Worksheets - Printable Worksheets Welding Safety Showing top 8 worksheets in the category - Welding Safety. Some of the worksheets displayed are Welding, Arc welding safety guide, Degrees that welding fabrication, Wln azars, Cte mathematics in welding professional math iv unit, Developing welding safety concepts and behaviors through, Safety health of welders, Math on metal.

Welding shop safety worksheet

ICEV Welding Workshop Safety Worksheet.pdf - Welding Shop... ICEV Welding Workshop Safety Worksheet.pdf - Welding Shop Safety Directions: Fill in the blank. Common Causes & Prevention of Accidents 1. To prevent ICEV Welding Workshop Safety Worksheet.pdf - Welding Shop... School Texas A&M University Course Title ISTM 415 Uploaded By CountJellyfishPerson4040 Pages 6 Shop Safety Teaching Resources | Teachers Pay Teachers This resource includes 12 common sense safety responsibilities (handout) for use when working in a shop class or any class that uses tools and machines. Also includes a safety test based on these rules. The test has 3 true/false, 2 fill in the blank, 7 short answer questions with different shop scenarios, and a poster to create. PDF Welding, Cutting, and Brazing Checklist - Texas Department of Insurance Installation and Operation of Oxygen-Fuel Gas Systems for Welding and Cutting - 1910.253 Yes No Date corrected 1. Is acetylene generated, piped, or utilized at a pressure of 30 p.s.i. absolute pressure or less? .253(a)(2)? 2.

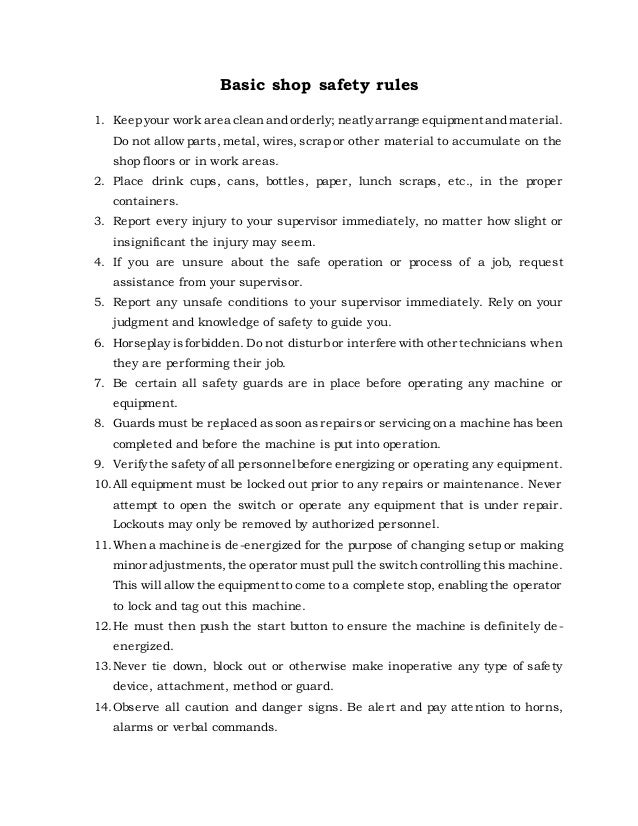

Welding shop safety worksheet. PDF General Shop Safety - Virginia Tech coats, etc. Shop clothing should not be loose, baggy or highly flammable. 2. Approved safety glasses must be worn at all times in the mechanics laboratory unless special eye or face protection is required. Approved safety glasses should be industrial quality. The Z 87.1 logo and the manufacturers emblem must be on the safety glasses for them to be PDF Welding Operations WORK LOCATION (ROOM NO.): DEPARTMENT: TOOL/MACHINE ... Safety glasses, work gloves 1i. Open axygen valve on torch body Incorrect adjustment could cause flame out, undesirable magnitude Safety glasses, work gloves 2. Perform weld 2a. Have flux and welding rods appropriate for type weld and material being welded Improper weld due to improper selection of flux and welding rods PDF Basic Shop Safety T U D N T 1. W O R K S H E T - PC\|MAC Accompanies: Basic Shop Safety 1 S T U D E N T 1. W O R K S H E E T Basic Shop Safety Directions: Fill in the blanks. _____ is the condition of being safe from risk or danger. 2. _____ are the major cause of death and injury for persons one to 37 years of age. Safety & Health Fact Sheets - American Welding Society Download these free Safety and Health Fact Sheets The free PDF documents below provide clear help in addressing common safety and health concerns. For more detailed information, refer to the free ANSI Z49.1 standard. Fumes and Gases Radiation Noise Chromium and Nickel in Welding Fume Electrical Hazards Fire and Explosion Prevention Burn Protection

Automotive Workshop Safety Checklists: Free Download - SafetyCulture Garage and Auto Shop Safety Checklist. Download Free Template. Automotive workshop owners can use this safety checklist to ensure that work areas are kept neat and orderly to avoid slip, trip, and fall hazards, employees are properly trained on safety procedures, and emergency equipment and protocols are available, among others. Worksheet .pdf - Basic Shop Safety Directions: Fill in the... S T U D E N T W O R K S H E E T Accompanies: Basic Shop Safety 1 Directions: Fill in the blanks: 1. _____ is the condition of being safe from risk or danger. 2. _____ are the major cause of death and injury for persons one to 37 years of age. 3. _____ (PPE's) are devices or equipment worn to protect students, teachers, employees or anyone who is working in a potentially dangerous area. PDF SAFETY COMPLIANCE CHECKLIST Welding Operations - Pacific Employers ŸWelding materials requiring ventilation or air-line respirators: cadmium, fluorides, zinc, lead, beryllium, mercury, stainless steel (oxygen cutting using chemical flux or iron powder or gas shielded arc). ŸMaterials to be welded is not known? House- keeping ŸAre aisles marked? .22 ŸWidth of aisles maintained? .22 welding shop safety Flashcards | Quizlet fumes All types of welding and cutting operations produce some sort of gases. Gas pressure Alone can injure a person if its not used properly. high The potential for fire and explosions in the welding shop. Dangerous If two or more welders are working in close proximity to each other they need to be aware that their arc radiation ca be hurt others.

PDF Quiz and Answer Key Welding Safety 13-026 - Family Insurance Center Answer Key - Welding Safety 13-026 1. Two of the more common types of welding are gas and shielded metal arc. True 2. The most common fuel used in OxyFuel Welding is acetylene. True 3. Shielded Metal Arc Welding joins two metals together by producing a laser arc between the base metals to be joined and a flux coated consumable electrode rod. PDF Shop Safety Manual - Baylor University Shop safety rules are to be posted. 5. Horseplay is forbidden. 6. Machines are to be inspected prior to use. a. Machines should NEVER be used if all guards are not in place. b. Machines should be placed out of service if: i. Guards are missing or damaged ii. Machine is damaged or not operating properly PDF Workshop Self Inspection Checklist (WELDING) WORK02 Workshop Self Inspection Checklist (WELDING) WORK02 Welding Areas and Operations Assessor Location Date This core checklist is provided by the Health and Safety Department as a template, which provides a basic framework for the conduct of a school self-inspection of the type of environment indicated. OSHA Welding Safety Equipment Checklist [Free] | SafetyCulture A welding safety checklist is a tool used to assess workers' safety throughout the entire welding, cutting, and brazing processes. It helps ensure compliance with regulatory standards including wearing of appropriate Personal Protective Equipment (PPE), welding equipment usage, and machinery inspections. Welding Safety Checklist

DOC Welding and General Safety Test - CTE Online In this shop there are: a) SMAW welders b) Oxy-Fuel welders c) GMAW welders d) All of the above 3. Safety glasses are to be worn in the shop… Always When you feel like it When sparks fly Only if they are in style 4. Any dangerous condition or injury to a person in the shop should be reported… When convenient At once At the end of class

welding symbols worksheet welding symbol drawing symbols interpretation blueprint definitions terms table plan course class simple welders arc. Welding Symbols | Location Of Elements Of A Welding Symbol That Needed . welders. Welding Symbols In Engineering Drawing safeworkmethodofstatement.com. Welding Shop Safety Worksheet - Ivuyteq ivuyteq.blogspot ...

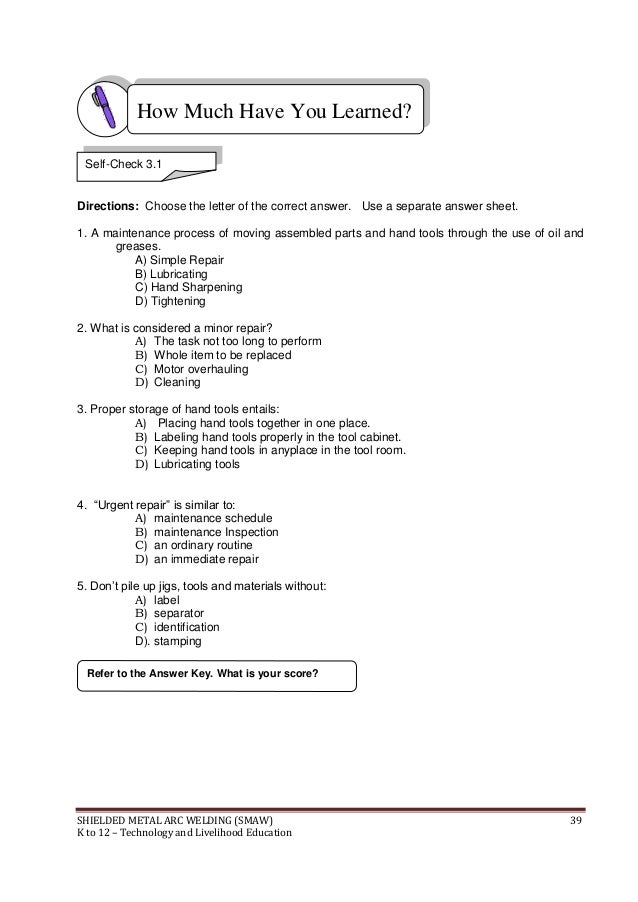

Safety Practices In Welding Safety Practices In Welding Worksheet Complete the following study guide. Use the Safety Practices In Welding Packetas your reference to gather the information. This worksheet is designed to help the beginning student with general safety practices in the welding shop and is also a good refresher for the advanced or returning student. Introduction

OSHA Welding Safety Requirements and Checklist The welding safety regulations described here center on hot work jobs such as welding, cutting, and brazing. These jobs can be hazardous, as they pose both physical safety and individual health risks. Half a million workers in a variety of industries are subject to illnesses and even fatal injuries.

Ag Welding/Mechanics General Safety Test - ProProfs Quiz Use recomended lifting points. D. Never get under a jacked up car that isn't properly supported on safety stands. Once a car is placed on stands it should be checked for stability. E. All of the above. 12. Eye protection (goggles, safety glasses and or face masks) are worn. A.

PDF Safety & Health of Welders - Hobart Welding School Welder Dressed for Light Duty Welding 6. Welder Dressed for Heavy Duty Welding 7. Precautionary Information for Oxyfuel Gas Processes 8. Insulating Devices on Terminals of a Welding Machine 9. Welding Helmet 10. Eye Protection Filter Shade Selector 11. Welding Station Using Transparent Welding Screen 12.

Construction Safety Handouts | WORK SAFE KENTUCKY First Aid. Avoiding Bloodborne Pathogens. Preventing Hypothermia. Emergency Eyewash and Shower Stations. Heat Safety. Protecting Construction Workers from Infectious Disease. Protecting Yourself from Ticks, Spiders, and Snakes. Tips for Hand Hygiene. Treating Sprains and Strains.

Welding Safety Equipment Checklist | KMS Tools and Equipment KMS Tools has a great selection of welding helmets. We recommend auto-darkening welding helmets for both new welders and experienced pros. Since you don't need to flip them up and down between welds, auto-darkening helmets make it easier to produce consistent high-quality welds. They also eliminate neck fatigue caused by flipping traditional ...

PDF Job Hazard Analysis Department: Welding Shop Welding Shop Date:, 2019 Possible Hazards or Task Describe Harm that could occur Hazard Rating (Low/ Medium/High) Control Action Personal Protective Equipment (PPE) Frequency of Monitoring Floor Jack Page 1 of 34 a) Pre-operation walk-around inspection. Clean any clutter surrounding machine and check for visible signs of wear. b) Place vehicle ...

Welding shop safety Flashcards | Quizlet Welding Material Safety Data Sheet First Aid Supplies Safety Data Sheet Terms in this set (73) Protective To prevent cuts, a person should always wear the proper ________________ safety equipment. Rules Failure to follow the proper safety procedures and _____________ will result in accidents. Safety

PDF Machine/Wood Shop Safety Inspection Checklist - Vcccd MACHINE/WOOD SHOP SAFETY INSPECTION CHECKLIST ... GAS/ARC WELDING Proper eye protection in use Warning sign present for welding Adequate ventilation Cylinders kept separated Electric cables in good condition Gas piping in good condition ...

PDF Welding, Cutting, and Brazing Checklist - Texas Department of Insurance Installation and Operation of Oxygen-Fuel Gas Systems for Welding and Cutting - 1910.253 Yes No Date corrected 1. Is acetylene generated, piped, or utilized at a pressure of 30 p.s.i. absolute pressure or less? .253(a)(2)? 2.

Shop Safety Teaching Resources | Teachers Pay Teachers This resource includes 12 common sense safety responsibilities (handout) for use when working in a shop class or any class that uses tools and machines. Also includes a safety test based on these rules. The test has 3 true/false, 2 fill in the blank, 7 short answer questions with different shop scenarios, and a poster to create.

0 Response to "41 welding shop safety worksheet"

Post a Comment